Tile adhesives are commonly used today in construction projects. To answer the question of why we should use tile adhesive instead of a cement-sand mortar mix, we will learn through this tile adhesive review article.

In this article, we will provide you with information about tile adhesive and suggest some best tile adhesive for wall and floor waterproofing. We stand at the most objective point of view to give these opinions.

What is tile adhesive?

Tile Adhesive is a premix and consists of carefully calculated ingredients such as Portland OPG Cement, carefully selected fine sand and additives to improve the properties of the tile adhesive.

High-quality tile adhesive can also be used to put tiles on old brick surfaces, on smooth cement surfaces, on wooden surfaces (with lining) or on other special surfaces.

This is a flexible material that does not shrink or crack due to changes in humidity and temperature. Therefore, tile adhesive is used to prevent peeling and cracking of tiles such as when tiling with cement. Besides, in addition to the function of fixing tiles, this material also has the ability to prevent water from seeping into the tile floor.

Moreover, the construction and use of tile adhesive are also very easy when you just need to mix it with water. There are even pre-mixed glues and you just need to stir them well before using them. Especially, in addition to the fixed-function, they are also used to prevent water from seeping below the tile subfloor.

Tile adhesive can be used for all types of tiles and in different areas such as outdoor walls, swimming pools, living rooms, bathrooms.

Why should you use adhesive for Floor and Wall Tiles?

Construction quality standards are increasing day by day. At the same time, the tile properties also change. The method of tiling with tile adhesive makes a difference when showing outstanding advantages in terms of use.

Some recent incidents of peeling bricks also show that tiling with oil lake still has many limitations. It is not suitable for some areas and modern tiles.

Here are the advantages of high-grade tile adhesive that make this tiling method increasingly popular, even mandatory:

#Tiling can be used for both high-class, large-format and low-absorbent tiles

Previously, ceramic floor tiles, also known as ceramic tiles, were very popular in the market. They are simple in design, low in functionality and small in size such as 30x30cm.

Therefore, when Porcelain tiles (porcelain tiles) were born, they almost dominated the market. Porcelain tiles meet the most stringent requirements of consumers. It has delicate pattern lines, hardness, scratch resistance, and very large size like 80x80cm or more than 1 meter.

However, Porcelain bricks are dense (fewer voids) and less absorbent. Therefore, they are not compatible with oil lakes, which can easily lead to peeling.

The newly born ceramic tile adhesive has solved the problem of today’s modern brick trend. Floor tile adhesive is not only suitable for ceramic tiles, porcelain tiles, granite tiles but also mosaic tiles.

Not only that, but tile adhesive is also used for large format tiles; even with sizes up to more than 1 meter that cement paste cannot meet.

#Convenient & fast construction

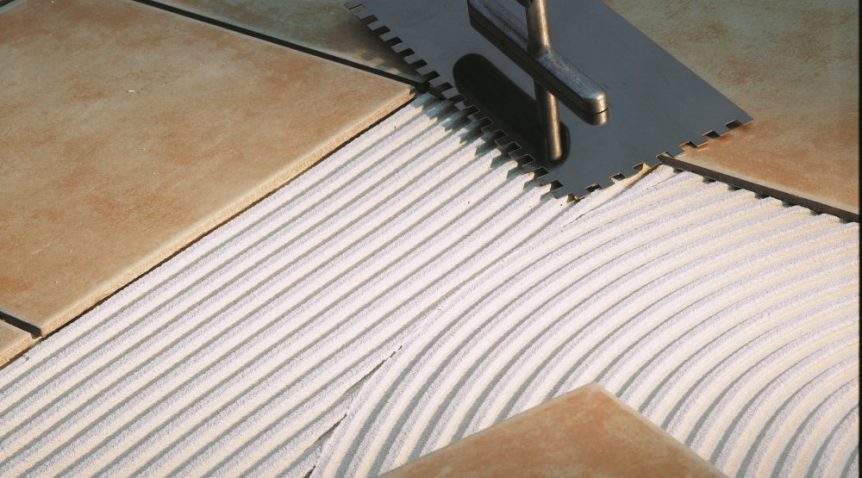

Use a serrated trowel to apply tile adhesive to help control the amount of glue used. Moreover, the serrated trowel will help the glue to be evenly and tightly covered on the substrate surface. As a result, the bond between the tile and the floor is optimal because the entire tile surface is in contact with the tile adhesive.

In addition, builders do NOT need to soak bricks in water before applying wall and floor tile adhesives. This saves considerable time and labor compared to the cement method.

Glue for wall tiles is very easy to use, just mix it with water according to the ratio provided and can be used immediately. Products are packaged for convenient transportation, low dust. As a result, the tile adhesive construction area is cleaner, easy to gather and does not take up much space when storing.

#Enhance the aesthetics and durability of the building

Tile adhesive allows masons to easily adjust tiles within a given period of time. This helps the tiles to be more aligned and brings a high aesthetic to the tiling area.

In addition, the wall tile adhesive is evenly spread on the surface to be tiled and the back of the tile to help create an even, strong and durable adhesion.

#Versatile

Tile adhesives are specially manufactured for special applications such as glass mosaic tiles, large granite tiles, tile adhesives on smooth surfaces, on drywalls, on old brick surfaces, exterior wall areas, gardens, parking lot, industrial area – factory, swimming pool area and other areas.

#Cost savings

Tile adhesive is much thinner than cement sand tiling, and this makes the texture lighter. 20kg tile adhesive can be used to tile areas with an area of about 4-5 m². Tile adhesive 25kg can be used to tile areas with an area of about 6-7 m².

Note that the coating thickness depends on the flatness of the foundation, construction tools and construction techniques.

Top 5 Best tile adhesive for wall & floor waterproofing Review

#1 Roberts 5900-1 Ceramic Tile Adhesive

Roberts is quite a popular brand of tile adhesives and many other products. They have a long history in the market, and they understand what customers need and want.

Roberts tile adhesive has advantages such as superior adhesion to conventional adhesives. It also possesses the good anti-skid ability, suitable for tiling of large format tiles, tiles with little and no water absorption such as tiles/granite, marble.

This product comes with a great price that allows you to complete large projects while keeping costs down.

#2 Red Devil 0497 Tile Paste Adhesive

Red Devil tile adhesive is considered a convenient and quick option for non-professionals to neatly complete their projects.

This glue gives good coverage with only a small amount of material. It’s already prepped and ready to go once you open the lid. Surely there won’t be any mess here with this glue stick.

Red Devil tile adhesive stands out in its good workability and stable adhesion. In addition, tiles can be adjusted for a considerable period of time after application. The slow setting time starting > 6 hours and ending < 9 hours is also an advantage of this tile adhesive

#3 DAP Weldwood Multi-Purpose Ceramic Tile Adhesive

Weldwood tile adhesive is known under the brand name DAP. This tile adhesive has high adhesion, specialized for tiling ceramic tiles, granite, large porcelain tiles, mosaic tiles, decorative tiles with low and very low water absorption, natural stone, or artificial stone.

You can use this glue for areas subject to a lot of weather, temperature, water pressure, and vibrations such as swimming pools, elevators, facades, gardens, or balconies.

Weldwood tile adhesive with a composition of cement, selective aggregates, and polymer additives (commonly used in PVA wood glues). This glue has outstanding characteristics of colorfastness, good adhesion, anti-mildew, high flexibility, and environmental friendliness.

#4 Henry, W.W. 12097 QT #430 Tile Adhesive

This tile adhesive from Henry, W.W. Co. is produced directly in the United States with modern technology. This is a specialized tile adhesive product based on Cement which is researched and developed and manufactured according to a special additive formula.

Products are tested according to quality standards, ensuring user-friendliness and environmental friendliness. Just a small amount of matter is enough to bind the materials together.

Currently, this tile adhesive production line is being preferred by many projects because of its good features, ease of use, and most importantly, its affordable price, which is suitable for the needs of consumers.

#5 Weldbond 8-50420 Multi-Purpose Adhesive Glue

This glue from Weldbond is a versatile glue and can work well with many different materials, including tile and brick.

Weldbond tile adhesive has advantages such as high ductility, ease of construction, and time-saving construction. High adhesive ability, making the tiles not slip during construction as well as not shrink when curing.

The next highlight is that you can edit the tiles after you apply them in the time before the glue dries. You can also paint over this glue and it will remain untouched for several decades.

Instructions for properly applying tile adhesive

#Step 1: Prepare the surface

The surface of the substrates must be clean, free of dust, clean of grease, not stagnant water and not too dry.

Tiles should not be soaked in water, must be sure that the tiles are clean and dry before gluing.

#Step 2: Mix glue

This step only applies to tile adhesives in powder form, for ready-made adhesives, skip this step.

You should put water in the bucket first and then put the tile glue in. Before mixing, pay attention to the ratio of 5-7 liters of water corresponding to 25kg of dry glue. Therefore, you need to control the amount of water to avoid dry or wet glue or excess glue later.

Then mix this mixture for 5-8 minutes with a hand mixer. To make the mixture homogeneous and flexible, you should leave it for another 3-5 minutes and then mix it again, then 1-2 minutes to be able to use it right away.

#Step 3: Spread the glue

Spread a thin layer of glue on the surface to be applied and then use a serrated trowel to tilt 60 degrees on the surface of the glue layer to create a uniform thickness groove, helping to create high adhesion for the tile.

In case the tile size is larger than 25x25cm, you need to apply a thin layer of glue behind the tile.

#Step 4: Paste the tiles

After spreading the glue, stick the brick in the designated position and then use a rubber hammer to knock it evenly on the surface of the brick. Use a damp sponge to clean off excess glue and wait 24 hours after the glue dries before you grout.