Aquariums in particular and glass in general are notoriously fragile and virtually impossible to repair in most cases. However, with the use of tempered glass glue, we can restore your precious glassware, aquarium and restore its functionality.

The following article will acquaint you with the best aquarium glues, along with some very useful information for you.

What is Glass Aquarium Glue?

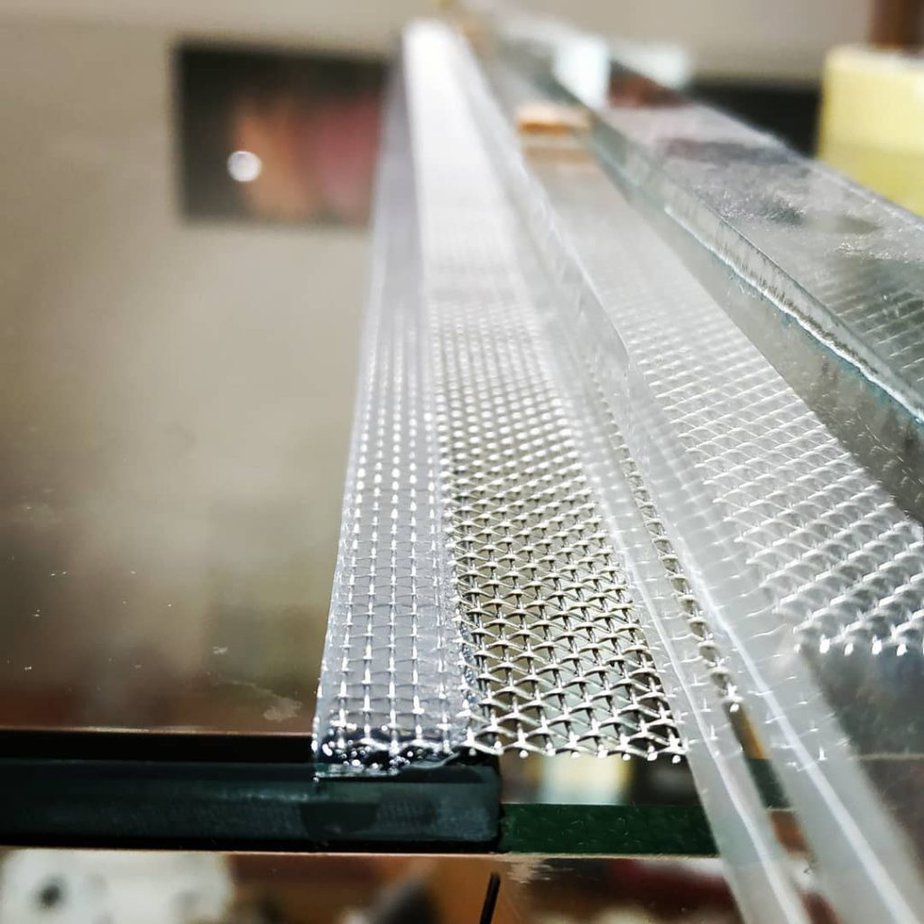

Glass glue is used to join glass surfaces together. Unlike other adhesives, glass glue does not require the bonding surface to be roughened or scratched. Glass glues are very suitable for gluing glass because they are highly effective even with their characteristic smooth surface. Using glass glue not only provides a solution for gluing the glass surface, but also allows you to glue the glass to wood or metal.

The type of glue you choose depends on what you intend to use it for and the materials involved. For example, gluing glass to glass requires a different type of adhesive to glue the metal and glass together. If the surface you are working with is in the kitchen, this will require a selection of specialized adhesives for this area.

Finding the best glue for glasses is not always easy. Each situation presents specific conditions for which we can evaluate and match the product information provided by the glass adhesive manufacturer. Then we will be able to distinguish which product is the best glue for glass.

What Are the Best Aquarium Glass Glue?

There are different types of glass glue products. In the next section, we’ll give you a detailed look at some of the commonly used adhesives, look at their different uses, and point out some important factors to consider when using them. use them.

#1 Silicone Glue

This versatile adhesive is suitable for use in aquariums such as aquariums and terrariums. Silicone is also commonly used in construction due to its simplicity of use and high durability. Although it is not transparent when dry, it offers excellent durability and elasticity as well as water resistance. High temperature resistant silicone is well suited for fireplace or oven repair.

For aquarium or terrarium repairs, you need to make sure your choice of silicone sealant is optimal for the purpose. Typically, silicone provides protection from mold growth in bathrooms and other areas. This is beneficial in humid or high humidity environments, however, these substances pose a danger to aquatic animals. Specialized silicone products can be found on the market for these purposes.

The product you need is Gorilla White 100% Silicone Sealant Caulk

- 100% silicone multi-purpose glue

- Ideal for sealing cracks or gaps between two surfaces

- Will not yellow, shrink or crack

- Provides resistance to mildew

#2 UV Glue

This adhesive comes in both high and low fluidity variants, making it effective almost anywhere. The formula allows for use in larger areas as well as for more detailed repairs.

In addition, UV glass glue provides high heat resistance and water resistance. UV glue for glass is most commonly used in furniture assembly and clear glass repair, and can even be used to bond glass to metal. Once you’ve finished applying it, the drying process requires UV light from a natural or artificial light source.

BONDIC Laser Bonding Tech Liquid Plastic is the right product.

- 100% waterproof and heat resistant

- UV light is activated to create a permanent bond

- Solvent-free formula stays liquid until light cures

#3 Food-safe glass glue

UV glues can also be used for applications that require user-friendly solutions, which means they must be non-toxic and unaffected by the environment of use. Generally, food-safe glass adhesive products are non-toxic, offer heat resistance of -50 to 120°C, are dishwasher-friendly, and are effective against oils, weak alkalis, and fats. fruit. Loctite Glass Glue is a great solution for this.

It is a reliable adhesive that bonds to all types of glass, metal and plastic. It will not affect the health of the fish or harm their food. Loctite also clears dry and colorless glass adhesives for smooth repairs on non-porous materials. It is also safe to use on items found in the dishwasher.

LOCTITE Instant Glass Glue is a product worth the investment.

- Glue reliably bonds to all types of glass, metal and plastic

- Clear and colorless dry glue for smooth repairs on non-porous materials

- Quick-adhesive is safe to use on dishwasher-safe items

#4 Super Glue

Gluing glass to glass is a feature that some super glue products can do. They are not suitable for repairing expensive glassware, as the glue is difficult to remove once it has set, and is therefore not recommended as a first choice. Instead, when faced with a decision, you should choose another high-strength glass glue product.

Gorilla Super Glue Gel will help you with this problem.

- The running control gel formula is great for use on vertical surfaces

- Gorilla hard anti-clogging cap helps keep the glue from drying

- Specially formulated to increase impact resistance

#5 Epoxy Glue

This two-component or epoxy glue will only begin to set after the resin has combined with the hardener. The adhesive can then be applied and finished with tools when completely dry. This type of adhesive is usually available in a two-compartment box, thus avoiding the entire lengthy mixing process.

Epoxy adhesives can be used in various applications with materials such as metal, glass, stone and many plastics. It is important to note that two-component adhesives are not suitable for glass bonds with larger surface areas.

GORILLA Epoxy Glue is the product we highly recommend to you.

- Strong, permanent, fast and gap-filling adhesive for many surfaces

- Best for tough repairs requiring a strong bond and resistance to solvents

- Dries clean, dries within 5 minutes and is ideal for an easy, clean finish

#6 PU Glue

Polyurethane glue is a multi-purpose adhesive that is effective in many different applications. It is available in both single and dual component forms and can be used in applications with larger surface areas, as well as joining small items. PU adhesives can also be combined with different reagents such as inhibitors or quick-drying agents, reducing or increasing the curing time respectively. PU adhesive also allows the addition of fillers and coloring agents.

Gorilla Original Waterproof Polyurethane Glue is the first choice if you want to use this glue.

- Extremely strong and flexible glue that can stick to many surfaces

- Best for tough repairs on different surfaces, both indoor and outdoor

- 100% waterproof and won’t break when exposed to the elements

How to Choose the Best Glue for Aquariums?

Once you’ve assessed the damage of your glass, narrow down your search by looking at the glue that best serves the purpose. The durability and quality of the repair will depend on factors such as water and temperature resistance, adhesion strength, application process and curing time.

#1 Adhesive ability

The glass surface will require an adhesive strength suitable for its particular purpose. For example, a picture frame will take much less force and pressure than repairing a car’s windshield. So consider your need for repair work to choose the right glue.

#2 Use indoors vs outdoors

If you’re trying to repair interior or exterior glass, let’s cover some of the circumstances that will influence your choice of glass sealant. Exterior repairs will require a heat-resistant glazing adhesive that can withstand a wide range of weather and temperature ranges.

Water-resistant adhesive products are easy to find, but this type of glue is more commonly used in homes. Silicone or epoxy-based adhesives are more resilient when exposed to extreme heat or humidity, as you would often find in outdoor environments.

#3 Dry time

The time it takes for the adhesive to dry or cure is related to different aspects of the application process. Once applied, the time it takes for the adhesive to harden is called its setting time. While curing is the process by which the adhesive achieves the strongest bond to the surface. Some adhesives provide quick adhesion, with near-instant setting and curing, others may require some time for bondability to be maximized.

As we all know, superglue products provide instant adhesion and curing. On the other hand, Epoxy-based adhesives can require seven days to cure effectively, so are not suitable for quick and simple repair situations. Silicone sealants can cure in one or more days and this timeframe is affected by the density of the application.

#4 Waterproof

Some adhesives provide water resistance, while others are waterproof and seal the surface completely. Superglue products typically only provide water resistance, as the adhesives bind to the hydroxyl ions in the water. Continuous exposure to wet conditions will gradually degrade adhesion.

Epoxy-based adhesives can also be waterproof or water-resistant, specifically for the purposes of their application. If the repair area is flooded at some stage, use an epoxy that allows this.

Silicone is a widely used sealant for kitchen, bathroom, or even roofing purposes due to its long-lasting durability and waterproof formulation. A great option for repairing an exterior glass such as the windshield of a motor vehicle where it will need to withstand the weather.

#5 Heat resistant

Glass is a conductor of ambient air temperature and will retain its internal temperature for a while. Heat reduces the adhesive’s ability to effectively bond to the surface, which is why the sticker is easily removed with a hairdryer.

The transition temperature is the point at which the adhesive changes from a solid state to a more liquid state. Repairing a vase, for example, requires a much lower-temperature adhesive than a car’s windshield.

#6 Application

Silicone sealants and super glue products can be applied straight from the package, but epoxy-based solutions work differently. They need a chemical reaction to release their adhesive properties, so the resin and hardener are stored in separate containers. When combined, the recipe takes only a few minutes to solidify. Make sure you prepare the correct application tools and are familiar with each step of the process before you start mixing the epoxy.

How to Use Glass Tank Glue?

#Surface preparation

In this section, we will show you how to glue the glass. Here, attention to detail in every step of the process ensures its effectiveness. Gluing glass to glass is a delicate process in which shards of glass can cause a number of problems.

First, before starting the process, we need to assess the broken glass and consider the extent of the damage. When glassware breaks completely into small pieces, even the best glue for glass won’t help you. If you only have a handful of larger pieces to glue, you’ll need to put the pieces in a container and see how each piece fits together first. Once you have each part you need, you can start cleaning and preparing the glass surface for adhesion.

You will need to thoroughly clean and degrease each surface that you are working on. So start by using warm water with dish soap before cleaning your glasses with brandy or acetone. Once the surfaces are clean, avoid touching them with your bare hands as this can leave traces of oil and you will need to repeat the cleaning process. The presence of any grease or dirt will reduce the adhesion of the glue. It is recommended that you use rubber gloves for application and ensure that you allow the surface to dry completely before starting.

#Actual link of glasses

Start applying the glue, being careful not to apply too much to each surface, as this will cause the glue to flow out of the joint as you add each piece into place. Covering only one of the adjacent surfaces is generally sufficient, but consult the product information to be sure.

Once the glue has been applied, each piece is joined and held in place until the glue dries. Rubber clips, tape, or other tools can be helpful in this process. UV glue will require a UV lamp for the curing process, or you will require natural light for the assembly process.

It is difficult to predict how long curing will take, as this depends on the type of adhesive used, current environmental conditions and the type of material being incorporated. A curing time will be included in the product information provided, but in general it is always safe to let the adhesive cure longer than specified.

#Remove residual glue

You can use a paper towel or a piece of newsprint to gently wipe away excess glue. Repeat this process with the nozzle of the glue, as this will ensure that the cap is not permanently stuck the next time. You can also start the cleaning process around your work area.

A razor-edged tool can be used to remove dry glue from any surface. Once the glue is scraped off, you can wipe the glass again to make sure it cleans properly.

#Glue glass to wood

When gluing glass to wood, note the properties of each surface. Glass is dense and uniform, but wood is porous allowing liquids to seep below the surface.

In this case, use a special glass glue, apply it carefully and watch for possible streaks or bubbles. Even a small bubble is visible, so pay attention to detail in this part of the process.

If you need to mask the different light refraction angles of the glass and glue, you can simply paint the glass on one side before gluing it to the wood. When gluing wood to glass, you need to make sure the wood is clean, dry and free of dust. Any trace will greatly reduce the effective adhesion of the glue.

#Best glue for glass to metal

In order to bond glass to metal, there are many aspects that require your attention, as the adhesive surface can be difficult to work with. First, it is essential to consider the area size of each adjacent surface. The next factor to pay attention to is the temperature range to which the bonding surfaces will be exposed. As glass and metal expand at different rates when heated or cooled, we must assess where the material will be used as this will affect the process.

UV glue is well suited for this if the repair surface is almost smaller than your hand in the area. Larger surfaces are not resistant to high levels of mechanical stress.

For this purpose, it is recommended to use a glass glue with good elasticity such as a polyurethane or silicone based product.

Tips & Tricks for Gluing Glass Materials Properly

Glass shards can be dangerous to work with, so make sure your fingertips are protected with medical tape. This can reduce the risk of injury and will not limit your sense of touch or reduce your dexterity when working. Glass glue can be toxic, so to avoid contact with your hands, an extra measure of protection is to wear gloves. This will also keep you from leaving oily residue on any surfaces from your fingers.

Watch for glue fumes and make sure the area you’re working in has good airflow, even using a respirator if necessary. Be sure to protect your work area from any spills or drops of residue that may occur during application. Newspaper sheets are ideal for this purpose. Remember that it is much harder to clean up spills once the glue has set

Super glue products and heat melt adhesives do not have the strength required to glue glass to glass. For a temporary solution, you can simply use a hot glue gun, but keep in mind that only the previously mentioned adhesives such as silicone or polyurethane are suitable for permanent bonding.

Before starting construction and assembly, you may need to adjust the surface temperature by slightly warming your room. If it is too cold, it may lead to moisture condensing on the surface, negatively affecting the bonding and curing of the adhesive. When working with coated glass such as Plexiglas, be sure to test the adhesive on the surface before applying it to see if it will dissolve the coating.